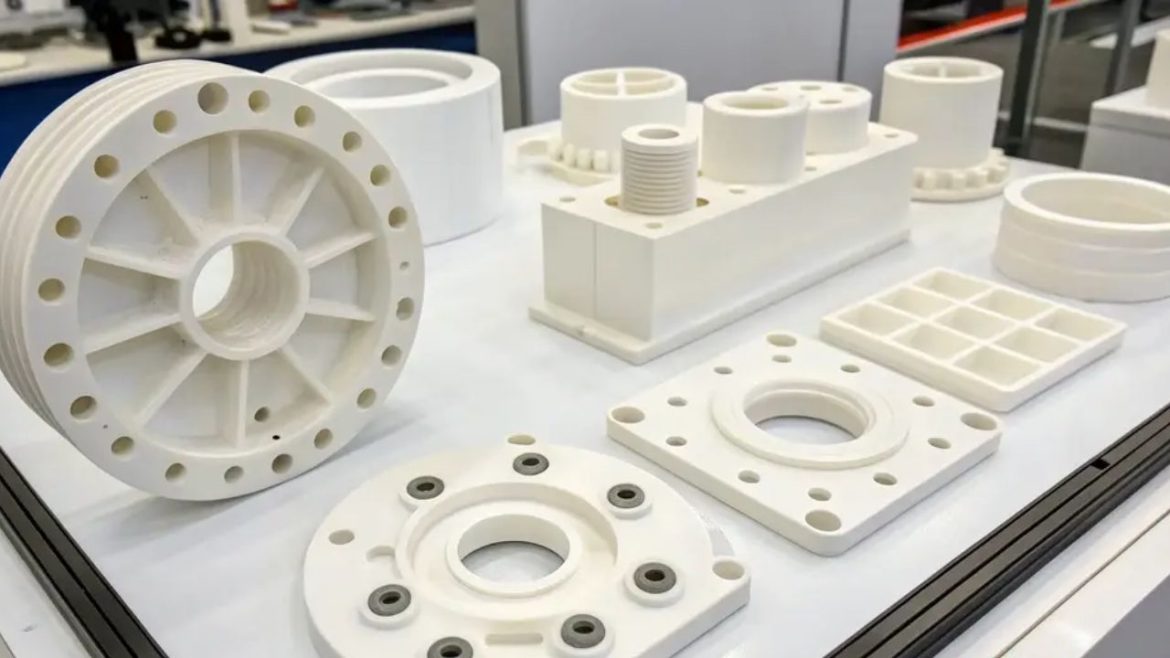

Precision components are fixtures that are necessary in the mold fixing, automated machinery, and assembly systems. These materials should have great levels of stability, wear resistance, and dimensional accuracy. Plastic-based materials, particularly POM (Polyoxymethylene) and industrial resins, have recently become widely used materials in the production of such components. They are the perfect substitutes for metallic parts in most applications due to their good mechanical performance and cost-effectiveness. The reasons why such materials are special are explained to assist manufacturers and engineers in making wise decisions when Checking Fixture Components.

Material Characteristics: Promote Precision

The initial reason why the use of POM and resin materials is commonly selected is their physical characteristics. POM can be considered very stiff in terms of high-dimensional stability, which is essential in parts needing tight tolerances. The stability and predictability under mechanical stress are also afforded by resin materials, depending on their formulation. This stability makes sure that the parts of the fixtures are accurate even when they are used for long periods or when subjected to different working conditions. Their low moisture absorption further increases the dimension consistency, as there is a great reduction in swelling or deformation.

Outstanding Machining: Complicated Designs

Components forming fixtures tend to have detailed geometries, fine slots, or points of assembly. POM and numerous engineering resins are characterized by their high machinability, enabling manufacturers to obtain the desired precise shapes with sophisticated machining methods using CNC machines. In comparison to metals, these materials produce lower tool wear, which in turn makes it possible to have higher processing speeds and lower machining costs. CNC high-speed machining is known to frequently produce component parts of fixtures in both POM and resin, providing clean edges and faces, and repeatability. The advantage is particularly valuable in areas where the production process must be quick and the quality must be high.

Durability and Wear Resistance

POM and engineering resins do surprisingly well in the work that involves friction, movement, or recurrence of mechanical interaction. Specifically, POM is self-lubricating, thus decreasing the friction levels between parts and extending the life cycle of parts in automated systems. Most resins have the ability to sustain high quantities of wear without mechanical integrity loss. They are also resistant to chemicals and solvents and can therefore be used in places where metal components are prone to corroding or degrading. Consequently, manufacturers are using these materials more often to guarantee the stability of performance in terms of longevity and performance in the case of the fixtures.

Lightweight Parts of Fast Machinery

With the current automated systems, lessening the weight of the internal components can also help a lot in enhancing the overall performance and energy efficiency. The POM and resin materials are much lighter than those of metals like stainless steel or HSS, and they are strong enough to serve several applications of a fixture. They are also light, thus enabling the machines to move at high speed with less load on the moving parts, and eventually, increase productivity. The lighter design also makes it easier to handle manually, assemble, and change, a factor that makes factory operations safer and efficient.

Both Economical and Quality-Based

Cost is a significant factor in determining the materials to be used in the construction of fixtures. The POM and resin materials provide a compromise of cost and performance. Their reduced material cost, coupled with less machining time and low wear of tools, makes them cost-saving to the manufacturers. These savings are especially important in the case of large production batches or projects in which custom designs have to be created. Notably, this cost-saving feature is not at the expense of quality, since these materials are always of high quality that is demanded in precision fixture work.

Diversification in a Wide Range of Industries

The reason why POM and resin components are becoming more popular is that they are versatile. These materials find applications in the electronic, automobile, medical, and automated assembly machines industries. Their flexibility enables the engineers to create parts of the fixtures that can satisfy definite functional needs without necessarily using metals. This plastic gives POM and resin a solid option to be used in both standard parts and custom-machined fittings.

Conclusion

The use of POM and resin materials in the precision parts of fixtures is popular due to a combination of mechanical power, strength, and cost-maturity. They are also very suitable for contemporary manufacturing because of their tight tolerances, ability to carry out complicated designs, and ability to survive harsh conditions. With automation and precision engineering ever growing, these materials will be further used in the manufacture of effective and dependable component parts.