Mistakes to Avoid When Designing Custom Cosmetic Packaging

The development of the original cosmetic package is a very important process when developing a product that is distinguishable in the beauty market. Packaging is not just a container of a product; it conveys the identity of a brand, it safeguards the formula, and it influences the consumer to buy it. Nevertheless, even some established brands may commit some mistakes that may influence functionality, beauty, and market performance. The major players in the custom cosmetic packaging are not unaware of such traps and assist brands in avoiding them by providing appropriate planning and professional advice.

Ignoring Product-Formula Compatibility

The main error is the inability to account for the compatibility of the packaging material and the formula of the product. Some of the active ingredients, oils, or high-viscosity formulas can come into contact with plastic, glass, or metal parts and cause discoloration, leakage, or deterioration. Effective companies that produce cosmetic packaging ensure the thorough evaluation of formulas and choose the materials that maintain the product stability and effectiveness. Compatibility is an initial security measure that guarantees the security of the product and the brand name.

Overlooking Functionality and User Experience

The other fatal mistake is focusing on aesthetics and not functionality. Although eye-catching designs may appeal to the display shelves, bad packaging design may spoil the customer’s appetite. Hard-to-open, dispense, or store packaging may provide unpleasant experiences and loss of products. The top-selling firms strike a balance between the aesthetics and practicality of the design of the bottle, jars, pumps, and tubes so that it is user-friendly yet has a high-end look. Considerate functionality not only increases customer satisfaction but also brand loyalty.

Neglecting Sustainability Considerations

In the current market, with the increasing mainstream being eco-friendly regarding its needs, sustainability may be a big oversight. Brands that are only interested in their appearance and not the environmental impact of their packaging would easily be criticized by consumers and retailers. Best cosmetic packaging businesses incorporate sustainability in the initial stages of the design, i.e., recyclable mono-materials, refillable parts, or biobased plastics. Sustainable design not only minimizes the environmental impact but also meets the current consumer demands and needs, as well as the regulatory demands.

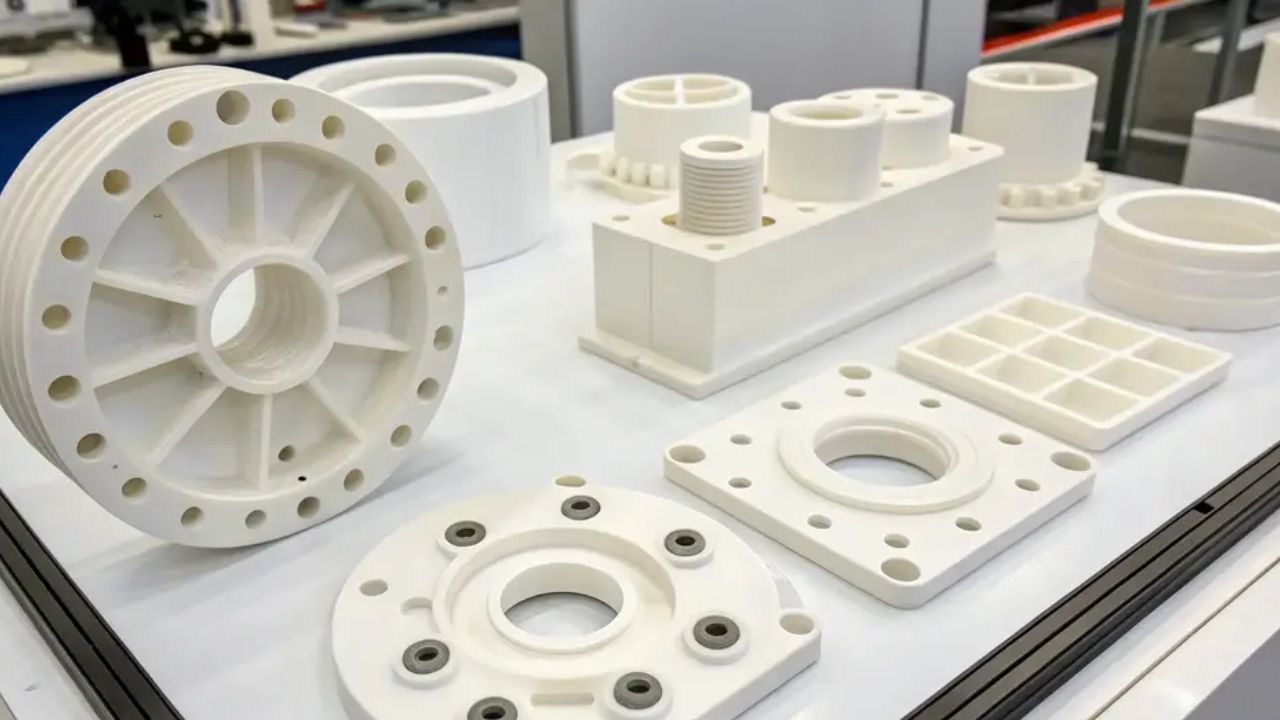

Underestimating the Importance of Manufacturing Feasibility

Although custom cosmetic packaging might be ideal in design drawings, it should be viable in large quantities. The most frequent error is designing complicated designs or thin shapes without evaluating the possibility of producing them in a stable and consistent fashion. The major manufacturers work in liaison with the brands to make sure that the design is feasible to be injection molded, to be blown molded, or some other method of production. Wall thickness, structural stability, and compatibility with fill lines are also taken into consideration by them to avoid expensive production mistakes or delays.

Skipping Early Testing and Prototyping

Failing to prototype and early test is a common mistake that may cause unplanned problems. The brands do not have the tools to test the ergonomics, dispensing performance, or aesthetic appeal fully without having physical samples. The major cosmetic packaging firms give quick prototyping and short-run samples to pilot designs in real life. This is done to enable the brands to discover the possible areas of weakness, like faulty pumps or unstable jars, before committing to mass production. Premature testing lowers risk, lowers the cost, and makes the end product satisfactory.

Overcomplicating Decoration and Surface Finishes

Despite the fact that quality finishes and ornamentation may add to a product, they will create practical challenges to avoid becoming overcomplicated. Complicated printing, embossing, or metallic coating may add time, cost, or possibility of defects to manufacturing. Experienced packaging manufacturers suggest that brands consider the types of finishes that are possible to provide a visual effect, and not to diminish the quality or efficacy of the production. The process of making the decoration simpler without compromising the brand makes the packaging functional and economical.

Conclusion

The customization of cosmetic packaging must be done in a careful manner with respect to various factors other than aesthetics. The availability of wrong choices, like not considering compatibility mode with formulas, not taking into account functionality, not taking into account sustainability, or even not prototyping the product, may violate the product performance, customer experience, and brand reputation. The most prominent cosmetic packaging firms can instruct the brands to overcome these obstacles, to make designs viable, effective, and business-ready. Through the elimination of the pitfalls associated with packaging and focus on aesthetics and functionality, a brand can design packaging that is not only attention-grabbing but also allows a better consumer experience and strengthens brand loyalty in the long run.